Description

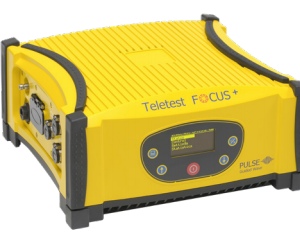

Over its 30-year history, ACFM technology has developed a solid reputation for accurately detecting and sizing surface-breaking cracks through paint and coatings. The original Amigo®ACFM instrument has earned a reputation for ruggedness, reliability, and ease of use. As the industry demands increased performance in speed, signal quality, and portability, it’s time for an evolution. It’s time for Amigo2.

Faster Inspections and Better Data

TSC Amigo2 is engineered around a highly advanced signal acquisition and processing system able to process data significantly faster than the original Amigo, for a data range that’s 14 times better. This offers you smoother, higher resolution indications that increase the detectability of small defects and the coating thickness through which you can inspect.

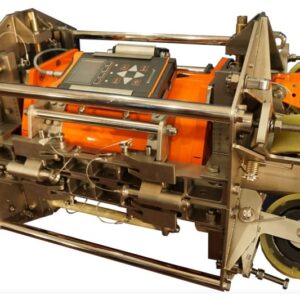

Portable Unit with Embedded and Remote Software

Amigo2 is a self-contained unit incorporating electronics, multi-touch display, and storage in one rugged enclosure. This removes the need for a remote computer and cables, enhancing portability. Of course, those of you who still wish to use a remote computer still can.

A New Platform for Evolution

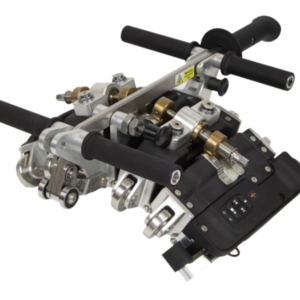

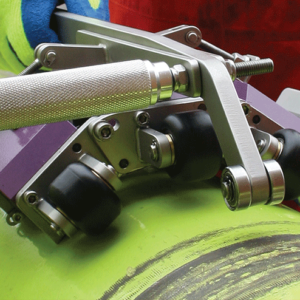

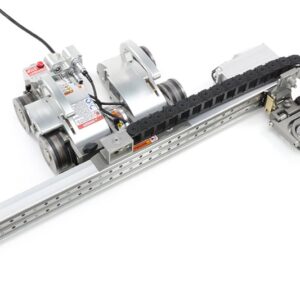

Amigo2 features a Sensu2 connector which will be used by a new generation of ACFM probes—manual or array. The Sensu2 connector supports up to eight digital inputs for high-speed, large-array applications. Together, Amigo2 and its Assist software are fully designed and ready to support the evolution of ACFM probes.

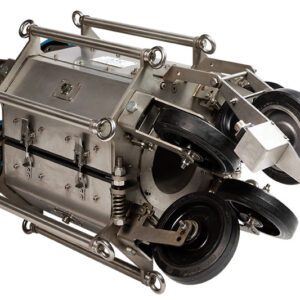

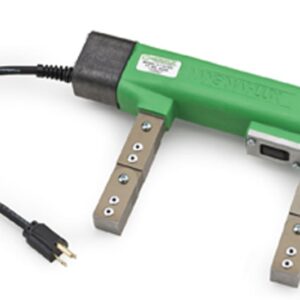

Backward Compatibility with Amigo and Pace Probes

Amigo2 comes equipped with a connector supporting the use of all AMIGO probes—array and standard manual probes—simply by importing the relevant QPC files. TSC Pace® pencil probes are also supported through a dedicated Sensu® connector. Furthermore, you can connect several probes to Amigo2 at the same time, rapidly switching between them in the software.

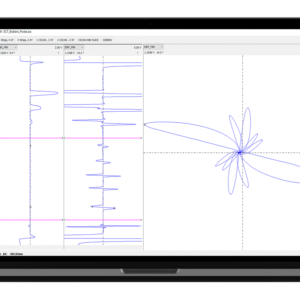

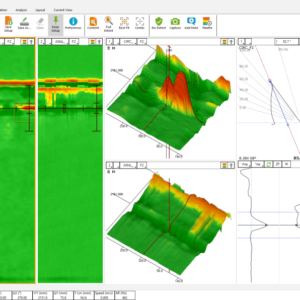

The Essence of ACFM: Assist

Experienced ACFM operators will feel immediately at home—with familiar Bx/Bz traces and butterfly taking center stage on the Amigo2 screen—while the multi-touch interface offers a highly intuitive access to all software functions in ribbon form.

Applications

Amigo2’s main focus is detecting and sizing surface-breaking cracks in a variety of metal components through paint and coatings. Its numerous application areas include:

- Weld inspection: w/ standard probes and single-pass array probes

- One or two-person operation (e.g., confined spaces)

- High-temperature applications

- Inspection through thick coatings

- Thread inspection

- Splash zone inspection

Specification

Dimensions (W×H×D)

355×288×127 mm (14.0×11.3×5.0 in)

Instrument weight

6.6 kg (14.5 lb)

Volume

13 L (791 in3)

Power requirements

100–240 VAC, 50–60 Hz

Power supply

Direct VAC or onboard batteries

Batteries

- Type: Li-ion, rechargeable, DOT compliant

- Typical life: 6–8 hours

Video output

HDMI

Display

- 26.4 cm (10.4 in)

- Multi-touch

- Non-reflective (AR coating)

- Anti-fingerprint – (oleophobic coating)

- 3 mm (1/8 in), chemically strengthened glass cover

- Optically bonded LCD and touchscreen

- Passive backlight enhancement

Connectivity

Gigabit Ethernet, Wi-Fi, Bluetooth®, USB 2.0 (×3)

Storage

SSD, 100 GB

Cooling

Sealed and fanless

Probe inputs

Sensu, Sensu2, Amigo

Frequency

5 kHz and 50 kHz

Data resolution

16 bits