Description

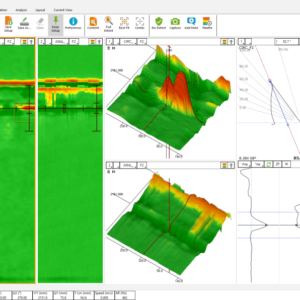

Teletest Focus+ was the first commercially available system to utilise long-range guided wave ultrasonic testing for detecting corrosion in pipelines. TWI developed the technology in response to requests from industrial members in the oil, gas and petrochemical industries. These companies required an non-destructive testing (NDT) method capable of detecting corrosion in pipes and pipelines at areas inaccessible for inspection by conventional NDT methods, i.e. insulated and sleeved pipework, or pipelines running under roads or elevated on pipe racks. The original Teletest equipment has been replaced by a system with greatly enhanced capability and the flaw detector is sold under the Teletest Focus + trademark.

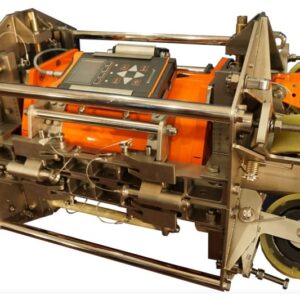

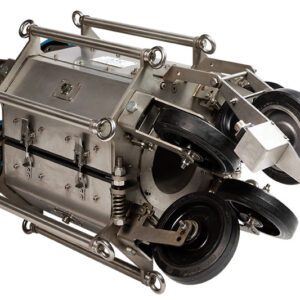

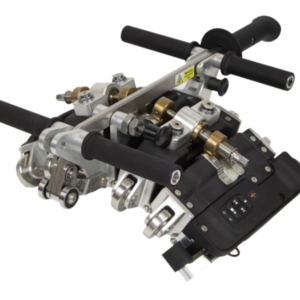

The basic system consists of:

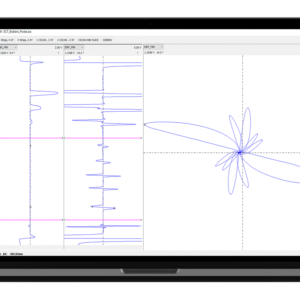

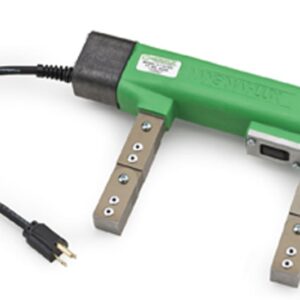

- A low-frequency flaw detector, the Teletest Focus unit

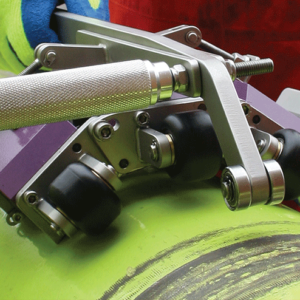

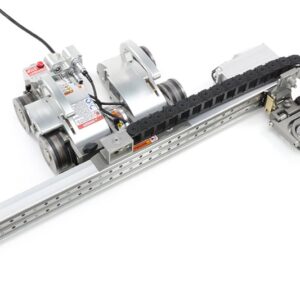

- Transducer ring or tool that wraps around the pipe

- A laptop computer that contains the software for controlling the system

- Cable connector between Teletest Focus+ unit and tool

- Umbilical between Teletest Focus+ unit and laptop

Specification

Weight

8 kg (17.6 lb)

Dimensions (W×D×H)

33×33×14 cm (13.0×13.0×5.5 in)

Standard input voltage

300 V, peak-to-peak

Transducer channels

80

Maximum averages

1 000 000

Maximum sample range

1000 ms

Receiving gain range

1–120 dB in 1 dB increments

Battery autonomy

10 hours, typical

Display

OLED

Air pump

Integrated, standard