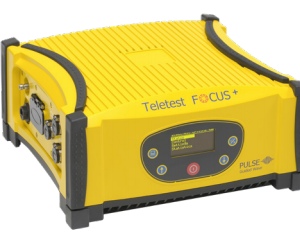

Description

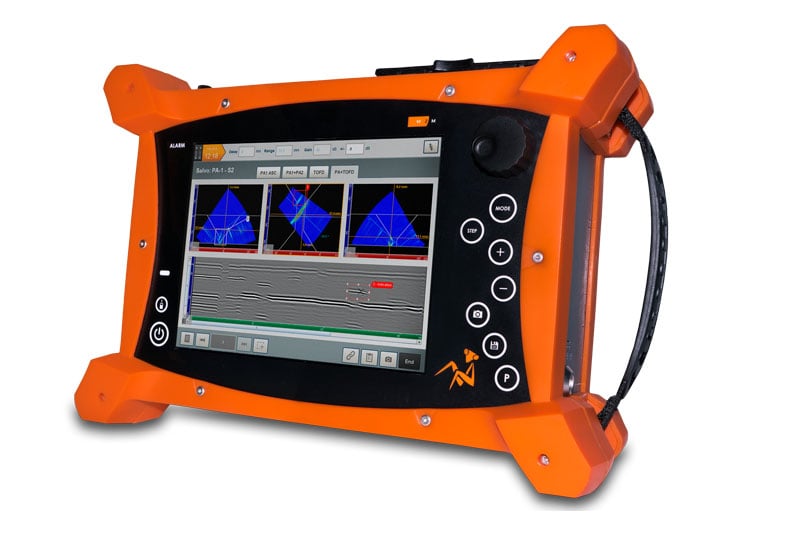

LIGHTWEIGHT 16:64PR PORTABLE PHASED-ARRAY FLAW DETECTOR

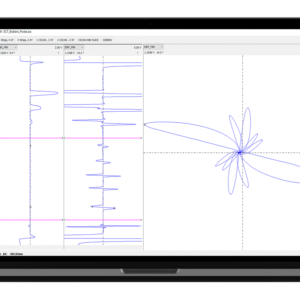

PAUT | sectorial, linear & compound scanning

Conventional UT | pulse-echo & dual techniques

TOFD | time of flight diffraction with lateral wave straightening

TFM | total focusing method in real-time for expertise

FULLY LOADED

- Real-time TFM

- Onboard PAUT calculator for all geometries Compound scanning

- Multi-group configurations

- High PRF

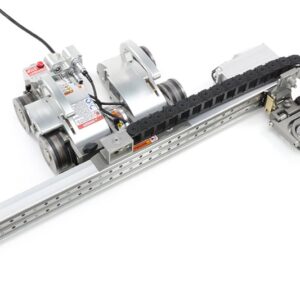

- Up to 3 encoded axes

- ISO & ASTM code compliant

QUICK SETUP TIME

- Intuitive interface, step by step app design

- 3-click TCG, TCG save and import

- 3-click material velocity

- 3-click probe balancing

- 3-click wedge calibration

- Onboard library of probes, wedges & scanners

- Onboard library of geometries and weld preps

- Application oriented templates

ONBOARD ANALYSIS

- 800% amplitude dynamic

- Cumulated volume views

TOFD lateral wave linearization - Customizable inspection report

- Dedicated analysis tools

- Fast Ethernet file transfer

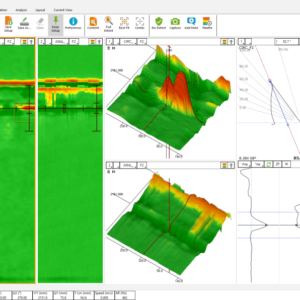

PC data analysis with CAPTURE

MANTIS comes in 3 cost-effective packages: Adept, Expert and Master.

MASTER

Key features:

- Hi-resolution TFM

- Matrixand dual arrays (DLA, DMA)

- FMC recording

Typical applications:

- Thick pipes, austenitic welds, limited probe access, 3D focusing

- R&D

EXPERT

Key features:

- 3-axis encoding

- live 3D-overlays

- 20kHz PRF

Typical applications:

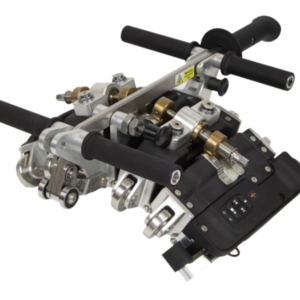

- Nozzle inspection

- T-, K-, Y-Joints

ADEPT

- PAUT + TOFD + PE + TFM

- Weld prep overlay

- CAD import

- Multi-group

- Quick TCG/DAC/AVG

- Quick calibration wizards

- Comes with CAPTURE for PC

- CIVA and ENLIGHT compatible

- Free data viewer

- Fast Ethernet file transfer + USB 3.0

- Unique flaw-detector with real-time TFM

Typical applications:

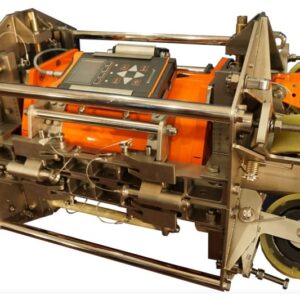

- Composite, Thin pipes, Corrosion

- Rope access inspections

General

L x W x H: 320mm x 220mm x 100mm

Operating temperature range: from -10°C to 45°C | 14°F to 113°F Storage temperature range: -10°C to 60°C | 14°F to 140°F with battery Operating time: 4h (hot swappable battery)

8.4‘’ high contrast resistive screen – resolution 1024×768 px Weight: 4,4kg with battery

IP65 according to CEI60529

Shock resistance according to MIL-STD-810G

Standard phased-array

Linear scanning, sectorial scanning, compound

Maximum active aperture: 16 channels

Phased array computation delay laws on plate, cylinder, T* & Y*, nozzle* Focusing mode: true depth, sound path, projection

Linear, matrix*, DLA and DMA* probes

Up to 6 probes | Up to 8 groups | Up to 2048 delay-laws CIVA fueled phased-array calculator

Real-time TFM

Reconstruction channels: 16 up to 64* Max number of points of reconstructed image: up to 65k Max refresh rate: up to 80fps Sound paths: direct (L or S), indirect* and converted* modes

Pulsers

64 phased-array channels:

Negative square pulse, width: 35ns to 1250ns Voltage: 12V – 90V with 1V step

Max. PRF: 12kHz up to 20kHz*

UT-TOFD:

Negative square pulse, width: 30ns to 1250ns Voltage: 12V to 200V with 1V step

Max. PRF: 12kHz up to 20kHz*

Receivers

16 phased-array channels:

Input impedance: 50Ω

Frequency range: 0.4 to 20MHz

Max. input signal: 2Vpp | TCG – ACG – DGS calibration wizard Gain: up to 120dB (0.1dB step)

Cross-talk between two channels < 50 dB

UT-TOFD:

Input impedance: 50Ω Frequency range: 0.6 to 25MHz Max. input signal: 2Vpp

TCG – DAC calibration wizard Gain: up to 120dB (0.1dB step)

Digitizer

Digitizing and real-time summation on 16 channels FIR filters

Real-time averaging up to x32

Rectified, RF, envelope

Resolution: 16bits

Max. sampling frequency: 100 MHz Digitizing depth up to 16k points A-scan range or delay max 65k points

Acquisition

Hardware acquisition gates

A-Scan/Peak data recording

FMC recording

Acquisition trigger on time, event, encoder

Max. data flow 150 MB/s on a 128Gb SSD Inspection data file size: up to 10Gb

Data transfer through Ethernet

800% amplitude range

Wizards

CAD overlay and 3D view

Real-time phased array calculator Base-time calibration for conventional UT Wedge calibration (angle, height) Velocity calibration

Scanner calibration

Amplitude calibration (TCG, DAC, DGS)

Probe design | Weld geometry design

Amplitude balancing

Part geometry with parametric shapes: plate, cylinder, T* & Y*, nozzle*

Analysis

Capture © software with analysis and reporting tools – Free viewer

A-Scan, B-Scan, C-Scan, D-Scan, Echodynamic, Top view, Side view, 3D view Analysis gates

Compatibility with CIVA analysis and ENLIGHT

Amplitude range: 800%

Overlay part geometry: plate, cylinder, T* or Y* section, nozzle* Overlay weld geometry

Customizable inspection report

I-O

Encoder inputs: 2 axes up to 3 axes*

1 IPEX connector for phased-array probe – can be upgraded to 2 with splitter* 1 USB 2.0 + 1 USB 3.0 + 1 mini display port + 1 RJ45 Ethernet

2 LEMO 00 connectors for UT-TOFD (1 PR – 1R) 1 external trigger

7 TTL inputs/outputs