Description

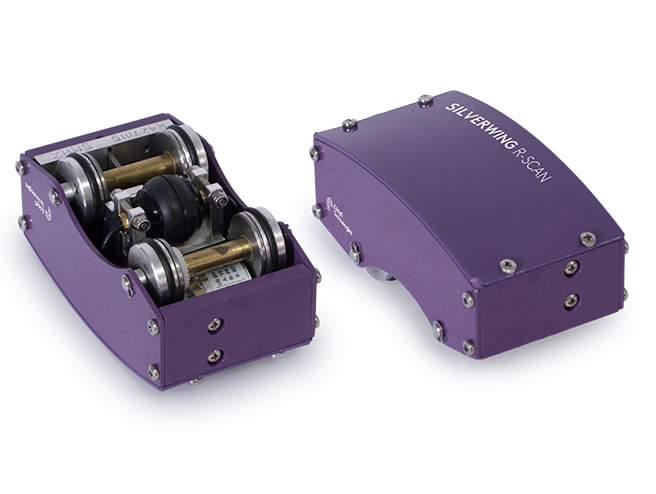

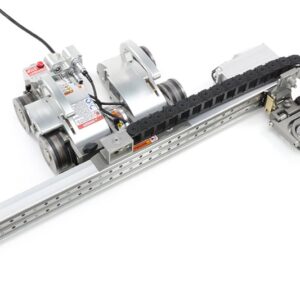

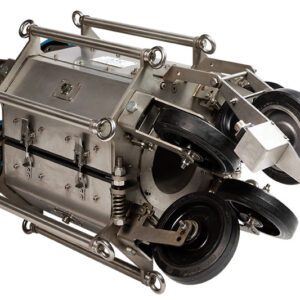

Designed for a wide range of components and with a high probability of detection, the R-Scan dry-coupled, handheld B-scan solution is perfect for ultrasonic testing (UT).

The System

Combining the R-Scan handheld, dry-coupled scanner with the Swift ultrasonic data acquisition instrument delivers a simple to use, battery operated, portable ultrasonic inspection system ideal for application ranging from 50 mm (2 in) up to flat plate. The software is packed with unique and intuitive features all design to improve productivity and user experience.

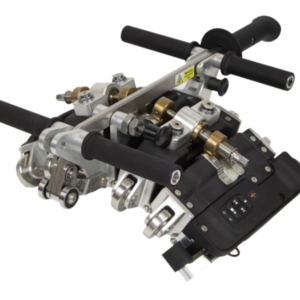

Probe Design

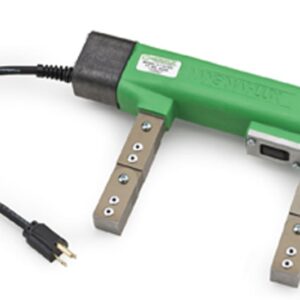

Designed to be used in remote locations and harsh petro-chemical environments, Silverwing’s unique dry-coupled ultrasonic wheel probe eliminates the need for couplant or a constant water supply. The probe, a dual crystal 5 MHz ultrasonic probe with a unique rolling probe face is capable of measuring material thickness ranging from 2.5 mm up to 100 mm (0.1 in up to 4 in).

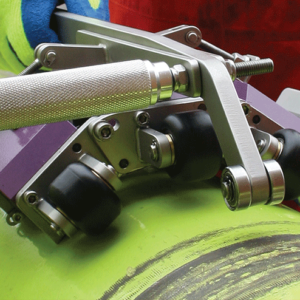

Scanner

R-Scan scanning head is fitted with an encoder to provide accurate positional information during an inspection. Magnetic wheels assist when scanning vertically of if inverted by minimizing the possibility of encoder slippage.

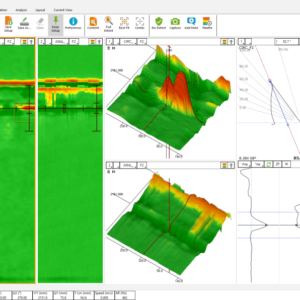

Floating and Tracking Gate

A unique feature of the system is floating and tracking gates. The intelligent gates allows for a tolerance in the initial setup and deliver a more accurate inspection. The gates travels with the signal as it moves up and down, and from side to side, reducing the likelihood of incorrect or missing data, allowing for a more reliable and complete B-Scan inspection data set.

High Probability of Detection (POD)

Compared to traditional spot thickness measurement, R-Scan increases the likelihood of detecting corrosion by continuously records thickness measurements as the scanning head is moved over the inspection surface. The captured thickness information is displayed as an A-Scan trace, a digital thickness measurement, an amplitude B-Scan or a simple to understand thickness profile.

Flexibility

R-Scan is an ideal all-rounder for inspection on tanks and pipelines. It can be used on a variety of components ranging from 50 mm (2 in) diameter up to flat surface with material thickness ranging from 2.5 mm up to 100 mm (0.1 in up to 4 in).

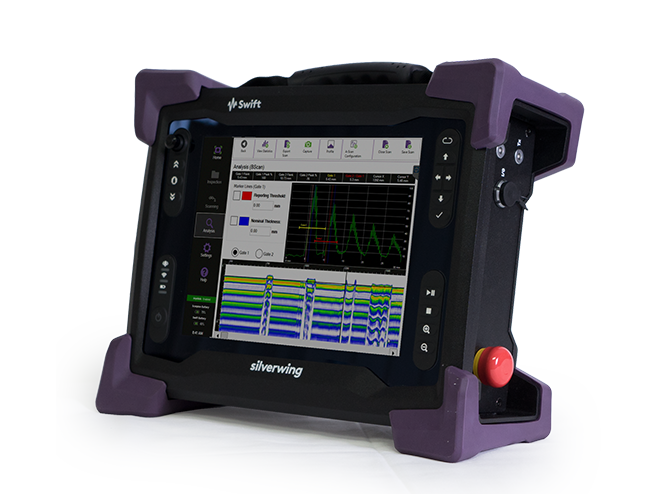

Swift

Swift has a large 26.4 cm (10.4 in) non-reflective, touchscreen display. Its magnesium alloy casing is tough, rated to IP65 and designed to protect the instrument against dust and water. With a 3 mm (1/8 in) strengthened glass display, it’s the perfect instrument for harsh environmental conditions. Supplied with two lithium-ion, hot-swappable batteries the instrument allows for a full day’s work. Swift has an optional harness to support the use of the system for longer period of time. The adjustable stand, the top handle, and four corner anchor points make it practical for on-site inspections.

Data Acquisition Software

The Swift software controls both the Scorpion2 and R-Scan. The intuitive software is easy to use with several advanced features resulting in high quality ultrasonic inspection data. Operators are guided through a simple process of entering the inspection details followed by ultrasonic setup. Adjustments can be made using the touch screen or hard buttons located on the Swift.

Data Collection and Analysis

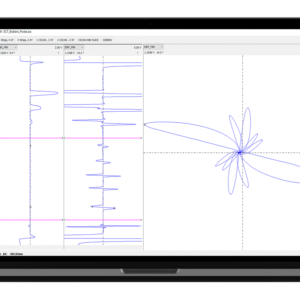

Real time A-Scan and B-Scan data is displayed during the scan. Once a scan is completed the operator can analyse the results or simply save the scan and move onto the next scan. Scan analysis is made simple with active A-Scan and B-Scan display, placing the cursor over any part of the B-Scan window shows the A-Scan trace and thickness measurement for that specific location. An adjustable threshold indicator can be displayed over the profile view, helping to identify reportable defects at a glance. The full amplitude view helps to characterize wall loss, allowing for a more detailed analysis and accurate corrosion assessment.

Reporting

Complete inspection data can be exported as a CSV or Excel file for statistical analyses and reporting. If preferred just A-Scan and B-Scan views can be exported as images files. For advanced reporting data can be exported as a CMAP compatible CMX file. CMAP software stiches all the scans automatically based on the export values, providing a complete overview of the inspection.

Specification

R-Scan

Dimensions (W×H×D)

65 x 54 x 122 mm (2.5 x 2.1 x 4.8 in)

Weight

1.8 kg (4 lb)

Umbilical cable length

3 metres (10 feet)

Max scan speed

Manual

Adhesion

Magnetic wheels and hand pressure

Transducer

5MHz twin element Dry-coupled

Near-surface resolution

2.5 mm (0.1 in)

R-Scan Capabilities

Minimum diameter

50 mm (2 in)

Maximum diameter

Flat plate

Minimum material thickness

2.5 mm (0.1 in)

Maximum material thickness

100 mm (4 in)

Maximum scan length

50 m (164 ft)

Minimum Surface temperature

0 °C (32 °F)

Maximum Surface temperature

80 °C (176 °F)

Swift

Dimensions (W×H×D)

355×288×127 mm (14.0×11.3×5.0 in)

Weight with batteries

6.6 kg (14.5 lb)

Weight without batteries

5.7 kg (12.5 lb)

Power requirements

100–240 VAC, 50–60 Hz

Power supply

Direct VAC or onboard batteries

Batteries type

Li-ion, rechargeable, DOT compliant

Battery typical life

6–8 hours

Display

26.4 cm (10.4 in), LCD touchscreen

Non-reflective (AR coating)

Anti-fingerprint (oleophobic coating)

3 mm (1/8 in), strengthened glass cover

Storage

SSD, 100 GB

Connectivity

Gigabit Ethernet, Wi-Fi, Bluetooth®, USB 2.0 (×3)

IP rating

Designed for IP65

Ambient temperature

0–40 °C (32–104 °F)

Ambient humidity

95 %, non-condensing

Ultrasonic

Internal pulser/receiver

1 x Tx/Rx, 1 x Tx (for pitch and catch)

Transducer frequency

2.25–20 MHz

Max. pulsing rate

Application dependant capable up to 20 kHz

Pulse voltage

-75 to -200 in step of 25 volts

Pulse width

25 ns to 225 ns in 2.5 ns increment

Damping

50Ω

Receiver gain

8 to 70 dB, 40 dB TCG Range

Filter, Waveform

FIR filter, Full rectify

Sampling rate

100 MHz

Resolution

16 bits

Waveform length

up to 16328

Trigger source

Internal or Encoder-based

Transducer range

2.25–20 MHz

Post trigger delay

8 to 141006540 samples in 1 sample step