Description

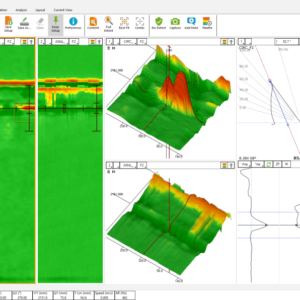

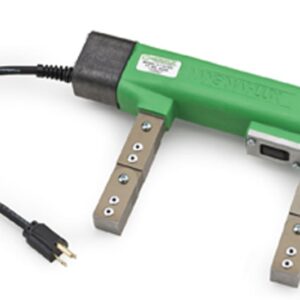

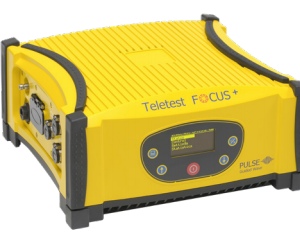

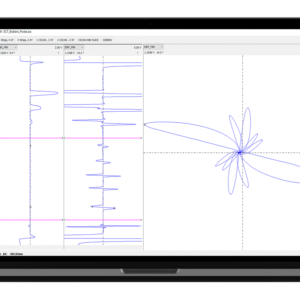

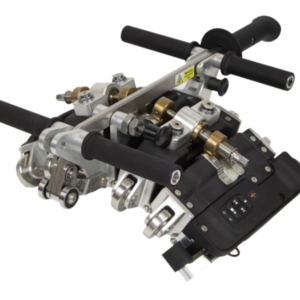

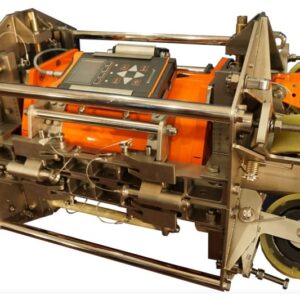

Magnetic-particle inspection (MPI) and liquid-penetrant inspection (LPI) are often used effectively to detect cracks. They are, however, impractical with known drawbacks—surface preparation, manual length sizing, lack of digital data. Sharck probes are designed around tangential eddy current array (TECA™), a better way to scan for fatigue cracks and stress-corrosion cracking (SCC). Use with the portable Reddy® test instrument, this is one of the most powerful integrated solution for pipeline integrity on the market.

Using TECA technology to assess cracks in pipelines, instead of MPI or LPI, you benefit from:

- Fastest solution on the market

- Surface-breaking cracks detection and sizing in one scan

- Interlinking cracks detection

- Easy to set up solution

- Simple calibration

- Very repeatable results

- Less user dependence

- Single-user operation with Reddy®

- In-service inspections

- Solution unaffected by weather conditions

- No surface preparation necessary

- User-friendly interface with data analysis assistant

- Complies with NACE Standard Practice SP0204

Specification

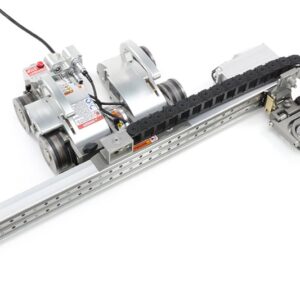

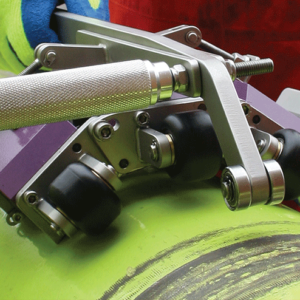

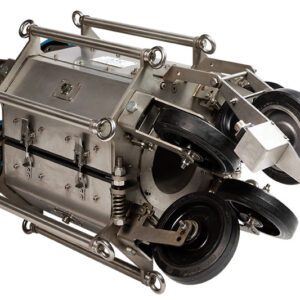

Casing

- Semi-flexible and conformable

Coverage

- 71 mm (2.8 in)

Minimum channel requirement

- 64

Compatible pipe diameters (NPS)

- 254–1220 mm (10–48 in)

Frequency

- Tuned and fixed at 100 kHz

Encoder

- Built-in, IP68 rated, 25 counts/mm

Cable

- 5m (16.4 ft)